Anodizing&Electroplate

Enhancing the properties and appearance of metal products, there are Anodizing, Zinc plating, Nickel plating, Tin plating, Gold plating, Silver plating, Copper plating, blackening, electro phoresis, and more.

Spray painting&Powder coating

In order to improve the aesthetics and durability of the product, there are 2 different properties of coatings, spray painting and powder coating, you can choose matte or gloss effect of the surface coating.

Silk Screen&Pad printing

Adding aesthetics to a part of the product or marking it with a logo message.

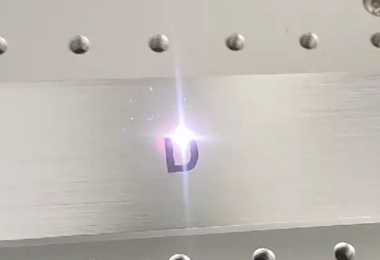

Laser engraving

Laser marking on the surface of the product with coded logo information and so on.

Polishing

The product is finely polished with different types of sandpaper multiple times and then polished. Different materials show different effects. For example, PMMA polishing has a highly transparent effect, and stainless steel polishing has a mirror-reflective effect.

Smooth&Sandblasting

If the product's roughness of Ra1.6μm cannot be met by machining, you can choose to Grind it to a finer specified position, or sandblast to obtain a uniform matte effect.

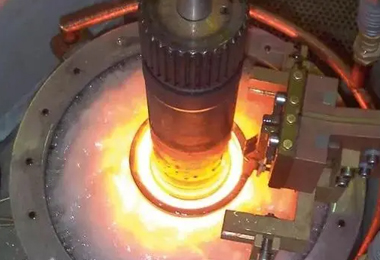

Heat treatment

Provide heat treatment and tempering of carbon steel and ferritic stainless steel such as Quenching, Tempering, Carburizing, nitriding, etc.