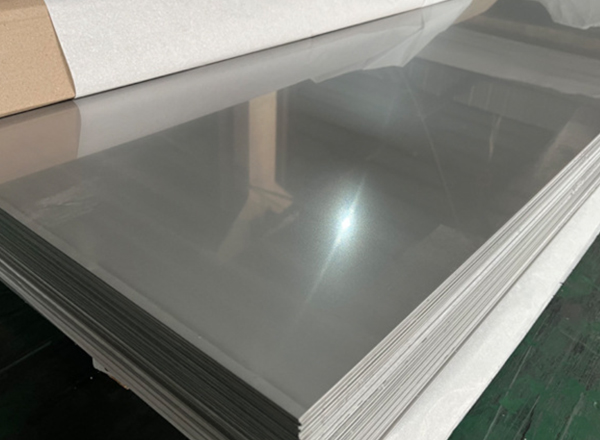

What is sheet metal?

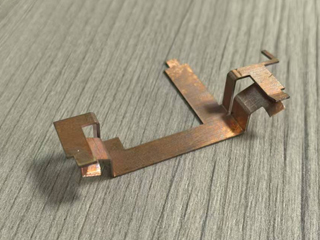

Sheet metal is a comprehensive cold working process for thin metal sheets (usually under 6mm), including shearing, punching/cutting/compounding, folding, welding, riveting, splicing and forming. Its distinctive feature is the consistent thickness of the same part. Products processed through the sheet metal process are called sheet metal parts and are widely used in various industries, such as car bodies, chimneys and tin stoves commonly used in households.

Common Materials for Sheet Metal

● Aluminium

● Carbon Steel

● Stainless Steel

● Copper

● Nickel